Scrap Material Façade

A real-world laboratory exploring digital tools for designing façades from surplus and reject materials.

Overview

Period: 2023 – 2024

Role: Software Developer, Research Collaborator & Lecturer

Context: University of Applied Sciences Erfurt (teaching), foundation 5+ architekten

Highlights

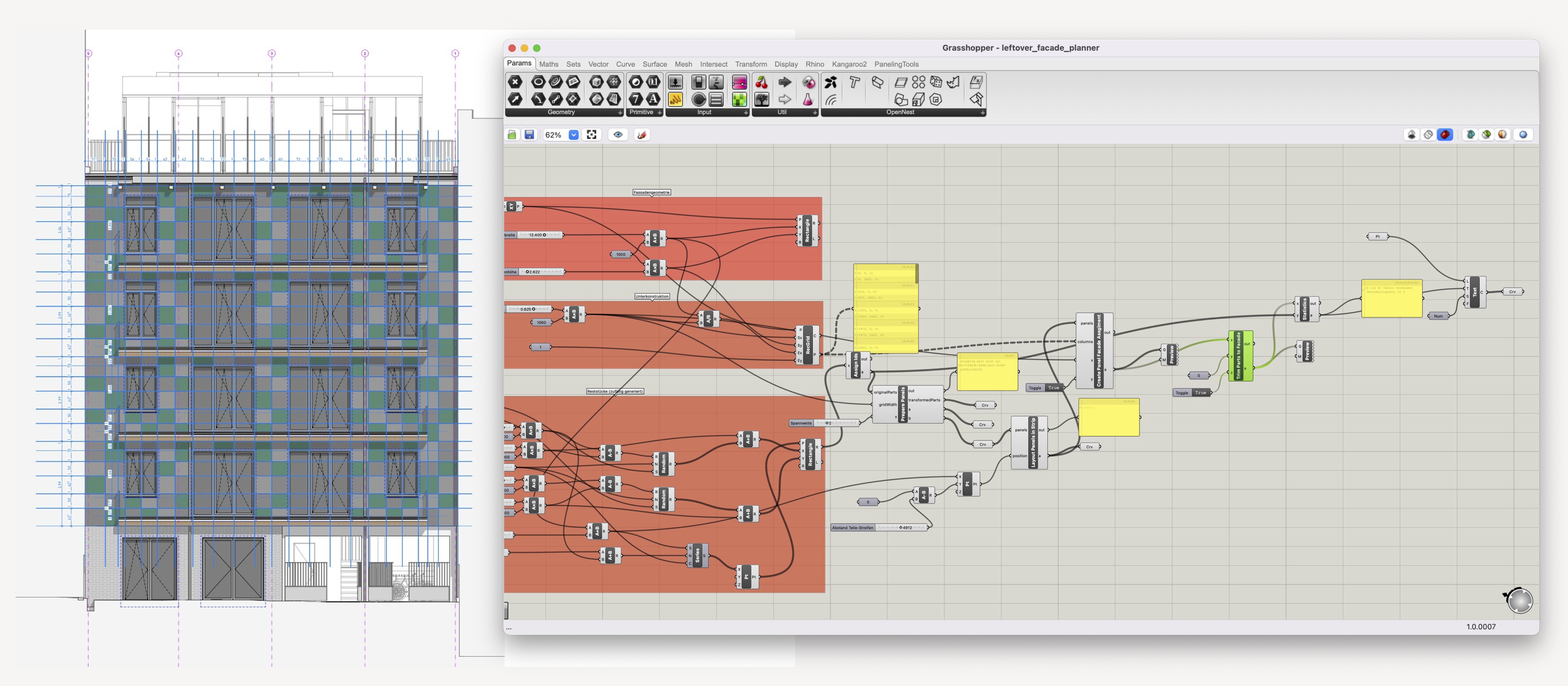

- Developed a digital workflow supporting material cataloguing, façade design and production planning.

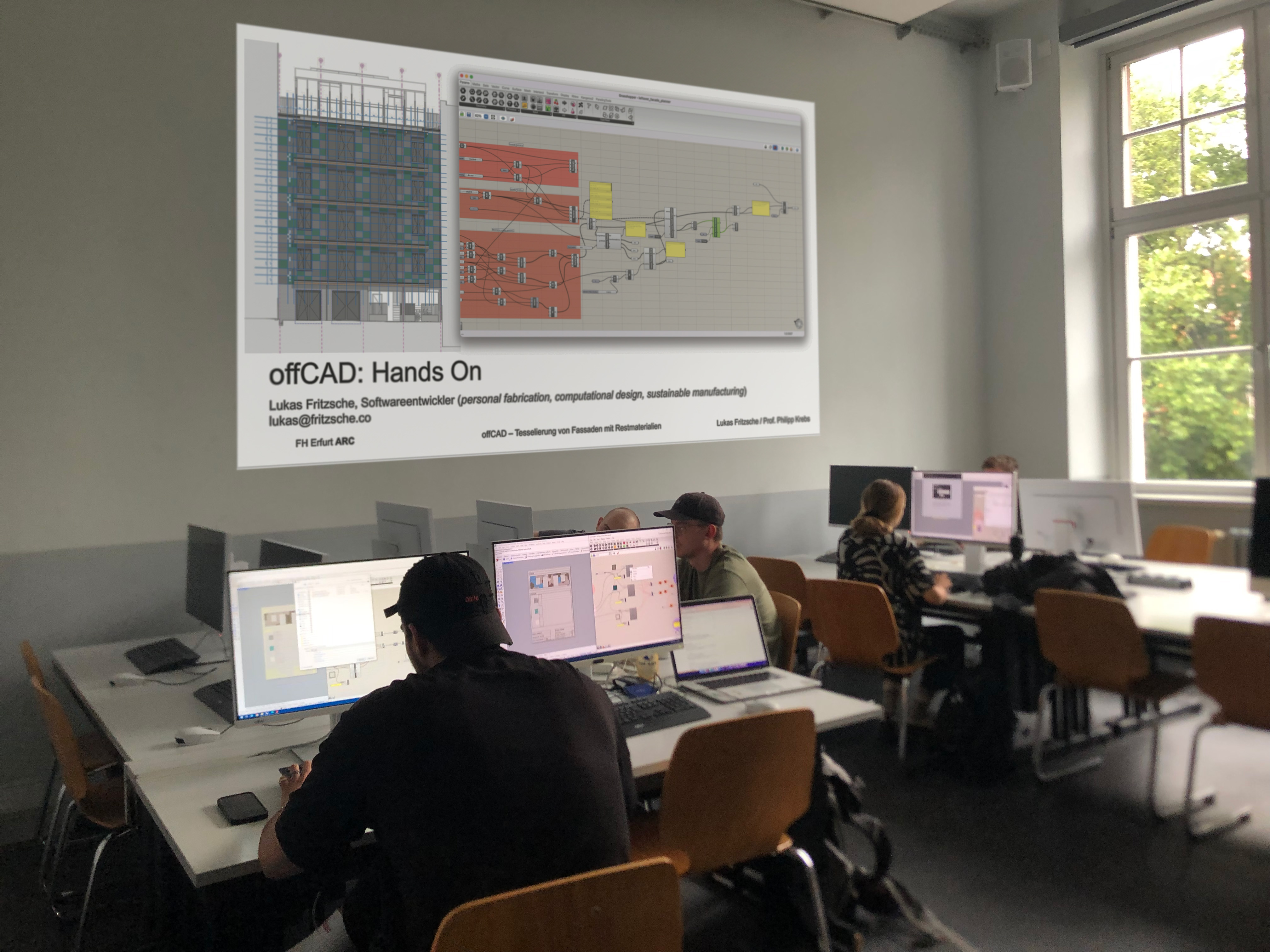

- Enabled students to experiment with parametric design and resource-efficient planning, by integrating real-time cut-plan optimization with a Grasshopper-based parametric tool for creating facade tesselations.

- Automated data transfer from material catalogues to 3D modeling and CNC fabrication outputs.

- Demonstrated the potential of digital tools maximizing degrees of freedom when designing with hard constraints introduced by material reuse

In-Depth

**

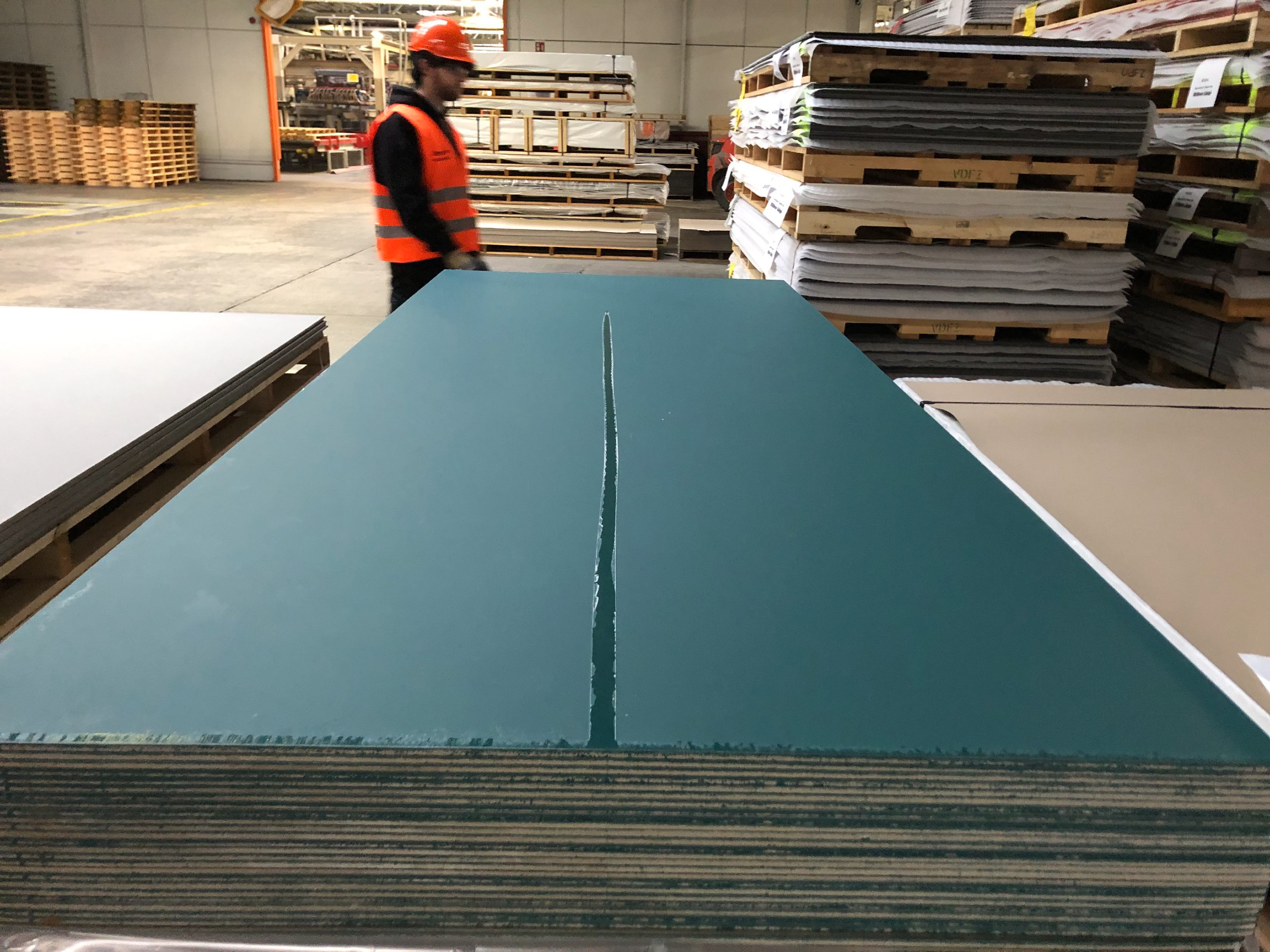

The Scrap Material Façade investigates how façades for urban timber buildings can be designed and realized using production reject fibre cement panels. The project links research, education, and architectural practice through a real-world laboratory (Reallabor) that connects digital design tools with sustainability-driven construction.

Conducted as part of a teaching and research program at Fachhochschule Erfurt under Prof. Philipp Krebs, and implemented in the built project Suffizienzhaus U10 by foundation 5+ architekten in Kassel, the experiment demonstrates how digital workflows can bring rejected yet technically sound materials back into architectural use.

A custom digital toolset based on Rhino3D and Grasshopper enabled the process within the different phases of material cataloguing, facade design exploration and fabrication planning.

The project exemplifies how digital design methods can turn material irregularities into a design resource rather than waste, advancing both sustainable construction and architectural education.

Technologies

Rhino 3D, Grasshopper, Parametric design, Material optimization, Nesting